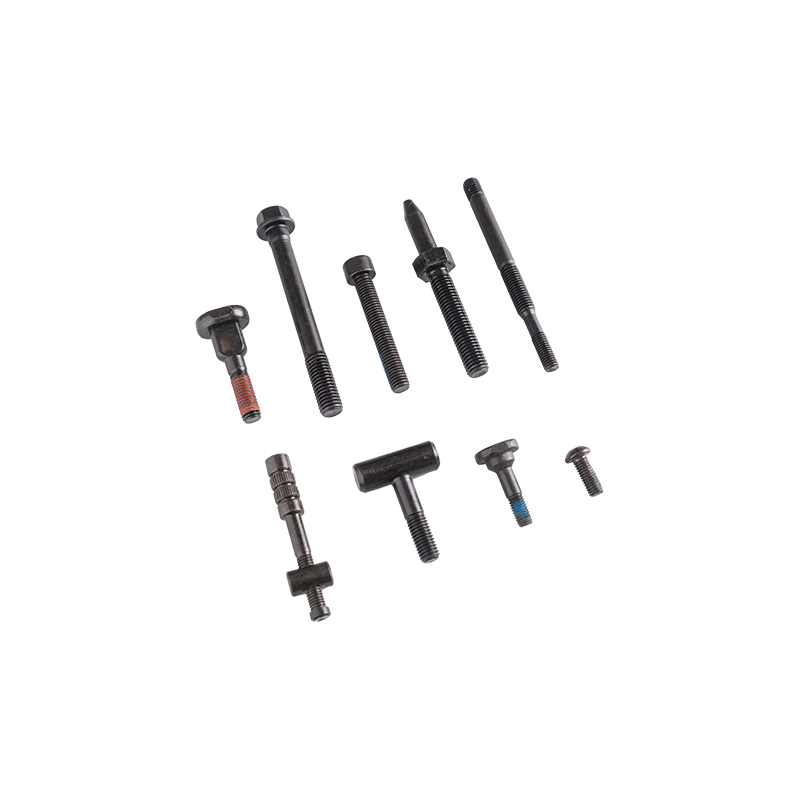

Determining the appropriate bolt size and length is crucial to ensure that the

Engineering bolts can perform its intended function effectively and safely. The process for selecting the right bolt size and length involves considering factors such as the load, material, and design specifications. Here's a step-by-step guide on how to determine the appropriate bolt size and length:

Understand the Application Requirements:

Begin by thoroughly understanding the specific application and the requirements of the joint. Consider factors such as the type of load (tension, shear, or combined), environmental conditions, and any design standards or codes that apply.

Determine the Load Requirements:

Calculate or estimate the load that the bolt will be subjected to. This load could be due to external forces, tension, shear, or a combination of these. Consult engineering calculations, blueprints, or structural analysis to determine the load.

Select the Bolt Material and Grade:

Choose the appropriate material and grade of bolt based on factors like the load, environmental conditions, and any industry standards or codes that apply. Different materials and grades have varying load-carrying capacities.

Refer to Design Codes and Guidelines:

Many engineering and construction applications follow specific design codes and guidelines (e.g., ASTM, AISC, AASHTO). Consult these standards for recommended bolt sizes and strengths based on the type of joint and the applied loads.

Use Bolt Sizing Calculations:

For standard joints, you can use bolt sizing calculations to determine the appropriate diameter and length of the bolt. These calculations take into account the material's tensile strength, shear strength, and the required safety factor.

Consider Joint Thickness:

The thickness of the components being joined is an essential factor. Ensure that the bolt is long enough to provide sufficient engagement and proper thread engagement in both parts. Generally, you want at least two full threads to extend beyond the nut.

Account for Clearances and Allowances:

Consider any necessary clearances, such as those for washers or other hardware components. Also, account for any allowances required for tightening the bolt and accommodating variations in manufacturing.

Check Thread Engagement:

Make sure that the bolt's threads fully engage with the nut or the tapped hole. Incomplete thread engagement can compromise the joint's strength and integrity.

Factor in Safety Margins:

Apply safety margins to your calculations to ensure that the selected bolt size can safely handle the loads. The safety factor typically ranges from 1.5 to 2, depending on the application and industry standards.

Consult with an Engineer or Expert:

If you have any doubts or if the application is complex, consider consulting with a structural engineer or a specialist in fasteners. They can provide valuable insights and recommendations.

Select the Appropriate Bolt Size and Length:

Based on your calculations and considerations, choose the bolt size and length that best matches the requirements of the joint, load, and application.

Verify Your Selection:

Double-check your calculations and consult with colleagues or experts to ensure that the chosen bolt size and length are appropriate.

It's essential to follow these steps carefully to ensure the safety and reliability of the joint. Using an improperly sized bolt can lead to structural failures or other problems in engineering and construction projects.

中文简体

中文简体

English

English

Español

Español

Deutsch

Deutsch

.png)