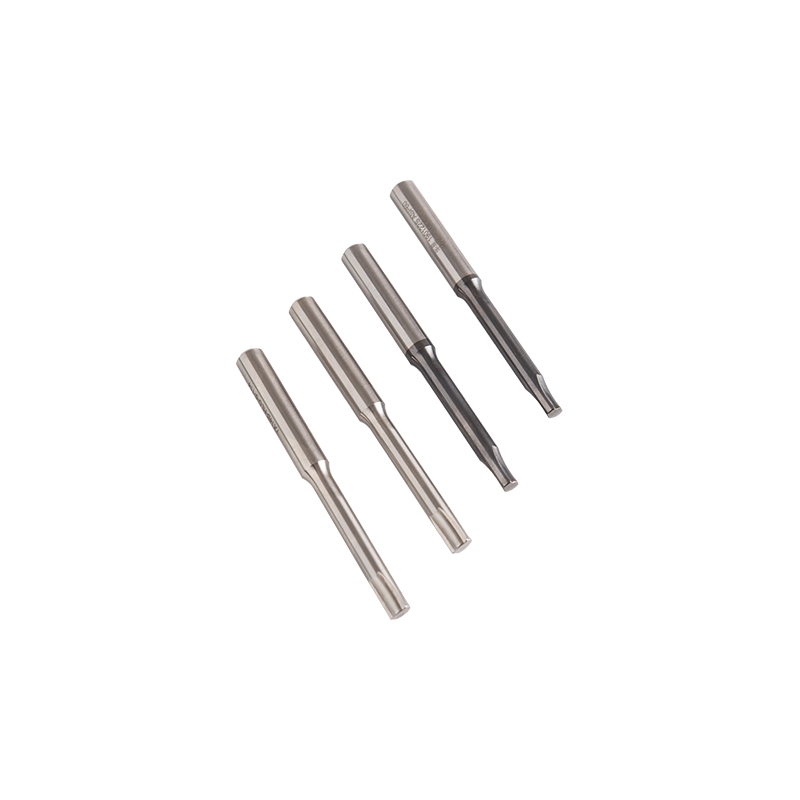

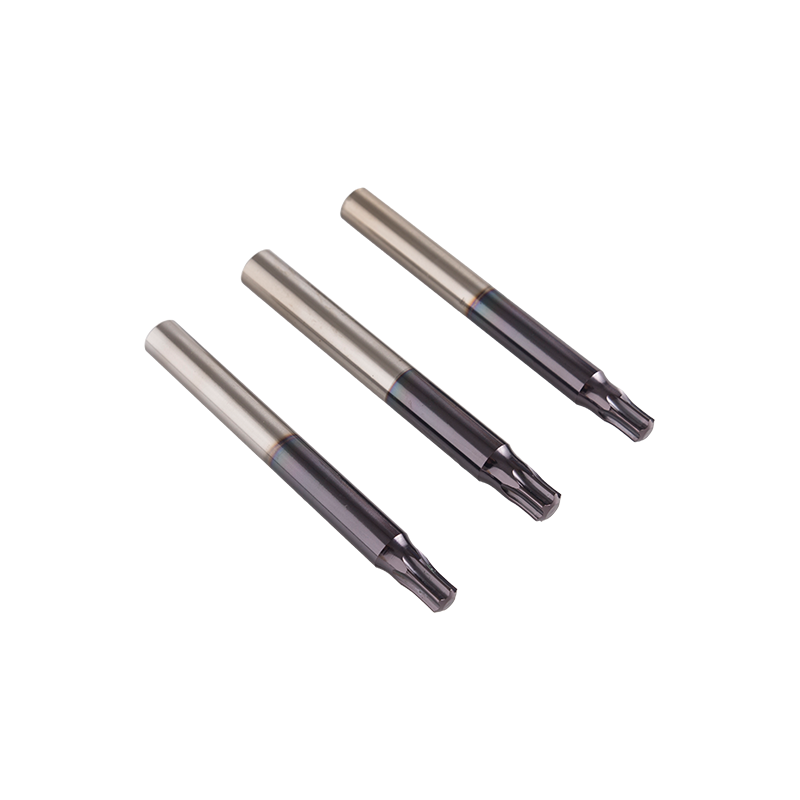

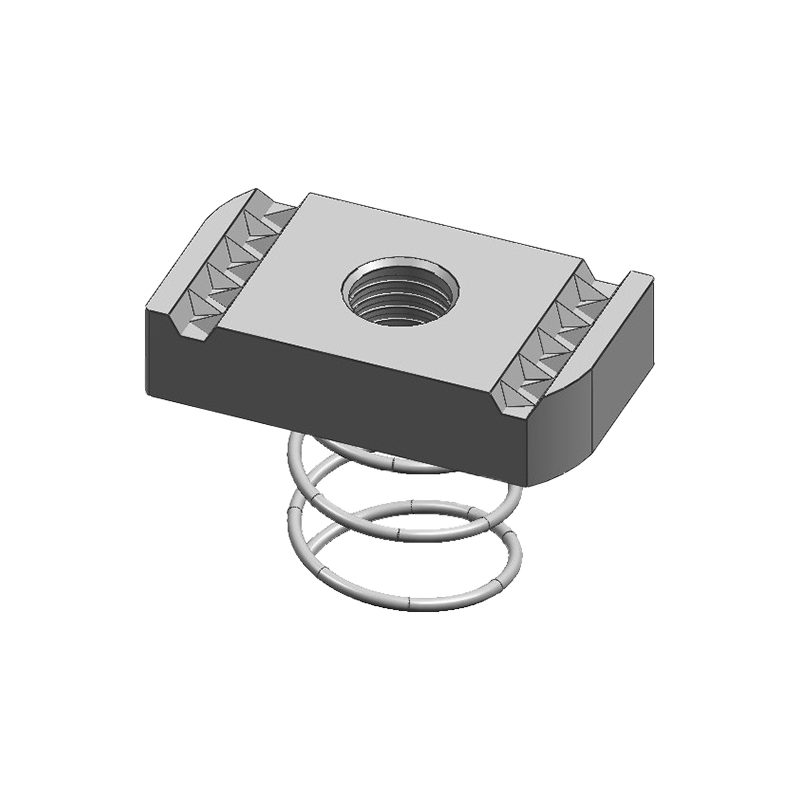

| Product name | Shaped punch |

| Material | M35 M42 |

| Size | 10mm-20mm |

| Surface coating | Titanium |

| Service life | 100,000-1 million |

Welcome to Jiaxing Taigor Machinery Co., Ltd.

-

Home +

- About us +

-

Products +

Bolt and Nuts Screw nut DM6A4692 Bolts DM6A4728 Auto Part Bolts Auto Parts Bolts Multi-Purpose Construction Bolts Spring washer Flange nuts Hex nuts Flat washers Long hex nutPunch and Dies Shaped K tube Shaped K tube Special-shaped push tube, punch Shaped K tube Shaped K tube Non-standard bottom plug Non-standard die Trimming die Multilayer Punch Shaped punch Shaped punch Special-shaped tool holder

-

Service +

- News +

-

Contact +

中文简体

中文简体

English

English

Español

Español

Deutsch

Deutsch