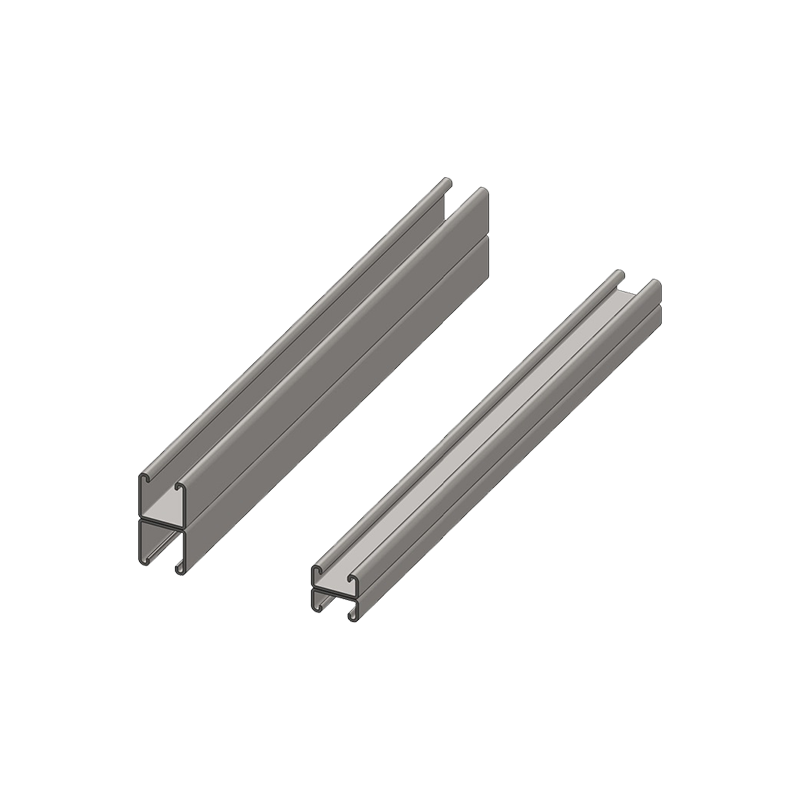

The fire safety performance of

engineering channel metallic is a critical attention in building design and construction. The behavior of metallic in fire depends on numerous factors, which includes its temperature, load-carrying capability at increased temperatures, and the presence of hearth protection measures. Here are key points concerning the fire safety overall performance of engineering channel metallic:

Temperature and Strength:

When exposed to fire, steel undergoes a reduction in power as temperatures upward push. Understanding the connection between temperature and the structural power of the channel metal is crucial in assessing its fireplace performance.

Critical Temperature:

The vital temperature is the point at which steel loses a full-size part of its load-bearing capacity. It's essential to decide the important temperature for the unique form of steel used in engineering channel construction.

Fire Resistance Rating:

The hearth resistance score is a measure of ways lengthy a structural element, which include channel metallic, can resist fire exposure at the same time as maintaining its load-bearing ability. Fire resistance rankings are frequently expressed in hours.

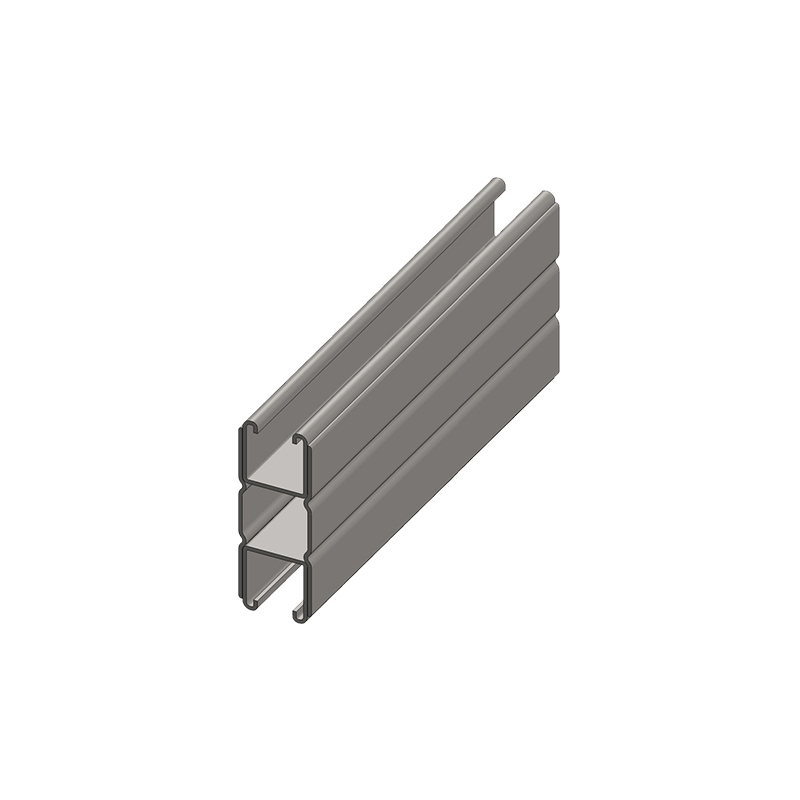

Passive Fire Protection:

Passive fire safety measures contain designing systems and deciding on materials to inherently resist the results of fireplace. Channel steel may be designed to have inherent fire resistance via its length, form, and cloth residences.

Fireproofing Coatings:

Fireproofing coatings may be implemented to channel metallic to beautify its hearth resistance. These coatings are designed to insulate the steel, delaying the growth in temperature and preserving its structural integrity for a distinct duration.

Intumescent Coatings:

Intumescent coatings are a kind of fireproofing coating that swells when uncovered to excessive temperatures, forming a protective insulating layer around the metal. This facilitates to sluggish down the rate of temperature upward thrust and extend the hearth resistance of the channel metal.

Encasement:

Encasing the channel metallic in substances with excessive fireplace resistance, which include concrete or gypsum board, can offer effective fireplace safety.

Fire Testing and Certification:

Fire trying out is carried out on constructing substances, consisting of metal additives, to evaluate their fireplace resistance. Products that meet particular criteria are frequently licensed by recognized trying out laboratories.

Design Considerations:

The hearth safety strategy for channel steel ought to be integrated into the general structural layout. This consists of considering elements which includes hearth compartmentation, structural fireplace engineering standards, and the hearth loading of the building.

Building Codes and Standards:

Compliance with nearby constructing codes and standards is important in ensuring that the fire safety measures for engineering channel metallic meet regulatory requirements.

Fire protection measures for engineering channel metal are an critical part of making sure the safety and balance of a shape in the event of a hearth. It's vital to paintings with structural engineers and cling to applicable codes and requirements to put in force effective fireplace safety strategies.

中文简体

中文简体

English

English

Español

Español

Deutsch

Deutsch