Product

Knowledge

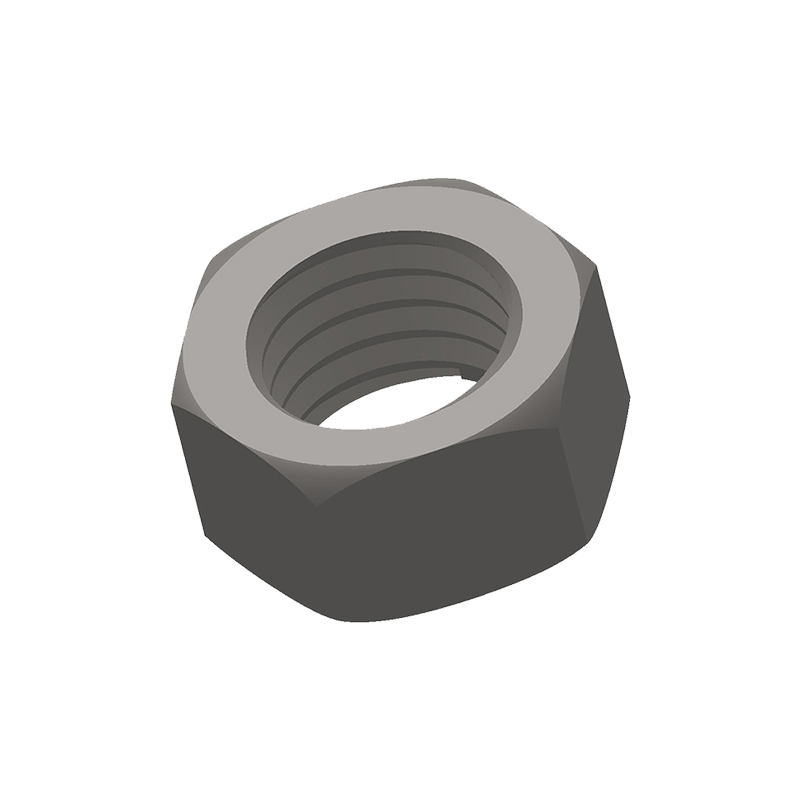

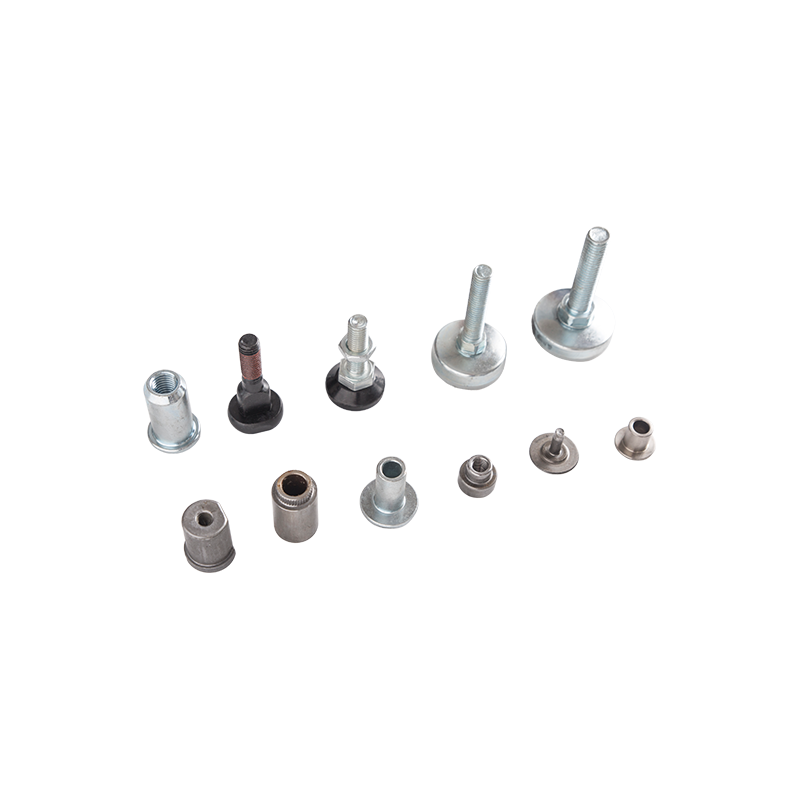

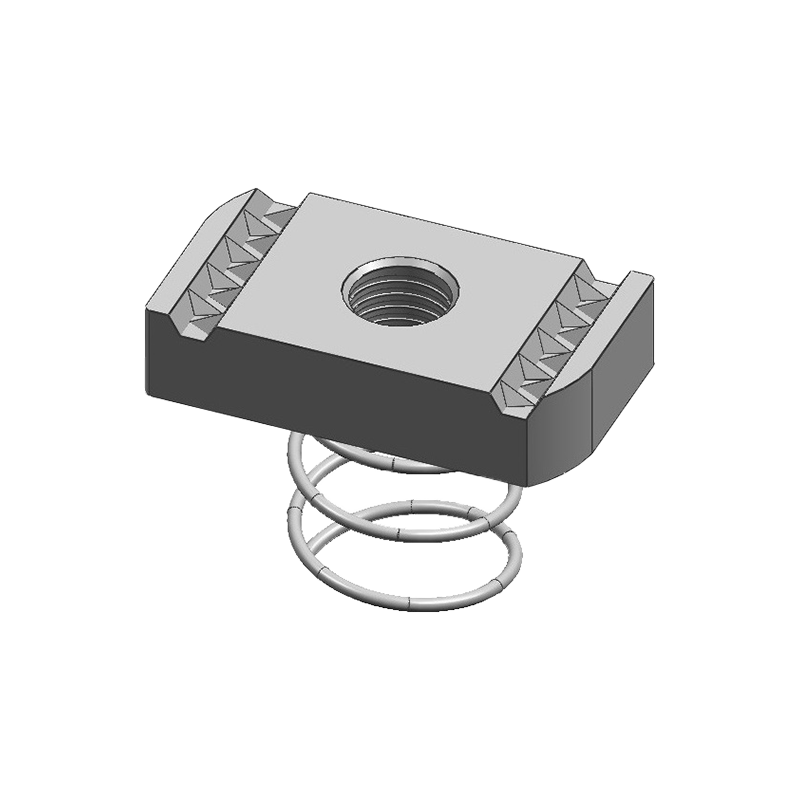

Hex nuts are one of the most common types of nuts used in engineering and various applications. They are named for their six-sided (hexagonal) shape, which allows for easy tightening and loosening with a standard wrench or socket. Hex nuts are essential fasteners in a wide range of engineering and construction projects. Here are some key characteristics and common uses of engineering hex nuts:

Key Characteristics:

Hexagonal Shape:

Hex nuts have a six-sided shape, making them easy to grip and turn with a wrench or socket.

Internal Threads: They have internal threads that correspond to the threads on bolts or screws, allowing for a secure and adjustable connection.

Materials: Hex nuts are made from a variety of materials, including steel, stainless steel, brass, and other alloys. The choice of material depends on the application's requirements, such as load-bearing capacity and corrosion resistance.

Coatings: Some hex nuts may have coatings or platings to improve their corrosion resistance or provide a specific appearance.

Common Applications:

General Fastening: Hex nuts are used in a wide range of engineering and construction applications to fasten components together, such as connecting bolts or screws to a variety of materials, including wood, metal, plastic, and more.

Structural Construction: In building and construction, hex nuts are used to secure structural components like beams, columns, and joints. They are often paired with bolts or threaded rods for added strength and stability.

Machinery and Equipment: Hex nuts are essential in the assembly of machinery and equipment, ensuring that various components, such as gears, bearings, and brackets, are securely fastened.

Automotive Industry: The automotive sector uses hex nuts for fastening various components, including engines, transmissions, suspension parts, and more. The automotive industry often requires specialty hex nuts like flange nuts and locking nuts.

Aerospace and Aviation: In aerospace and aviation applications, where precision and safety are paramount, hex nuts are used to secure critical components and structural elements.

Marine Industry: The marine sector uses hex nuts for assembling and securing components on boats, ships, and offshore structures. Corrosion-resistant materials are often required due to exposure to saltwater.

Electrical and Electronics: Hex nuts are used to secure electrical enclosures, control panels, and equipment in electrical and electronic installations. Specialized locking nuts are used to prevent loosening due to vibration.

Renewable Energy: In wind turbines, solar panel installations, and other renewable energy projects, hex nuts are used to secure components like tower sections, support structures, and electrical connections.

Plumbing and Pipelines: Hex nuts are used to secure plumbing fixtures, pipes, and valves in plumbing and pipeline systems.

DIY and Home Improvement: Hex nuts are also found in various DIY and home improvement projects for tasks like assembling furniture, installing shelving, and building structures.

It's essential to select the right type and size of hex nut for the specific application, ensuring that it matches the corresponding bolt or screw. Proper installation practices, including torque specifications and fastening procedures, are crucial for maintaining the integrity and safety of the connection in engineering projects.

中文简体

中文简体

English

English

Español

Español

Deutsch

Deutsch

.png)

.png)

.png)