Product

Knowledge

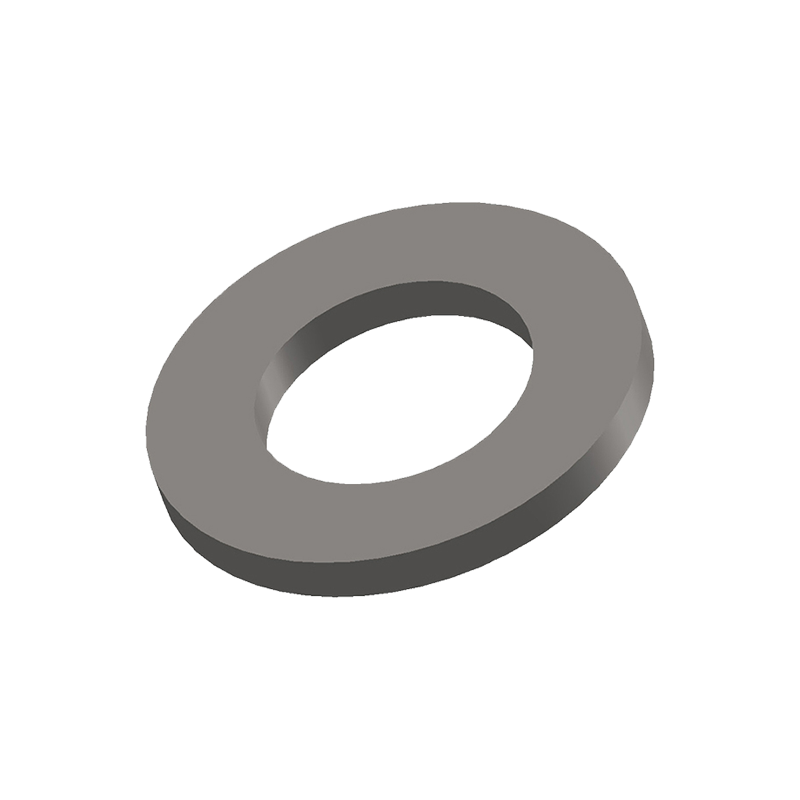

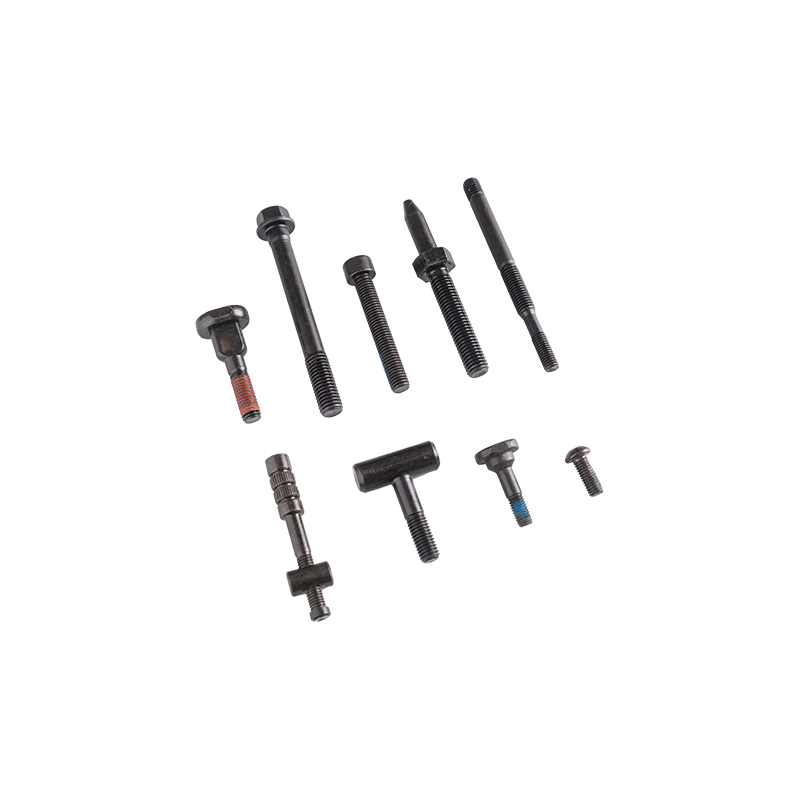

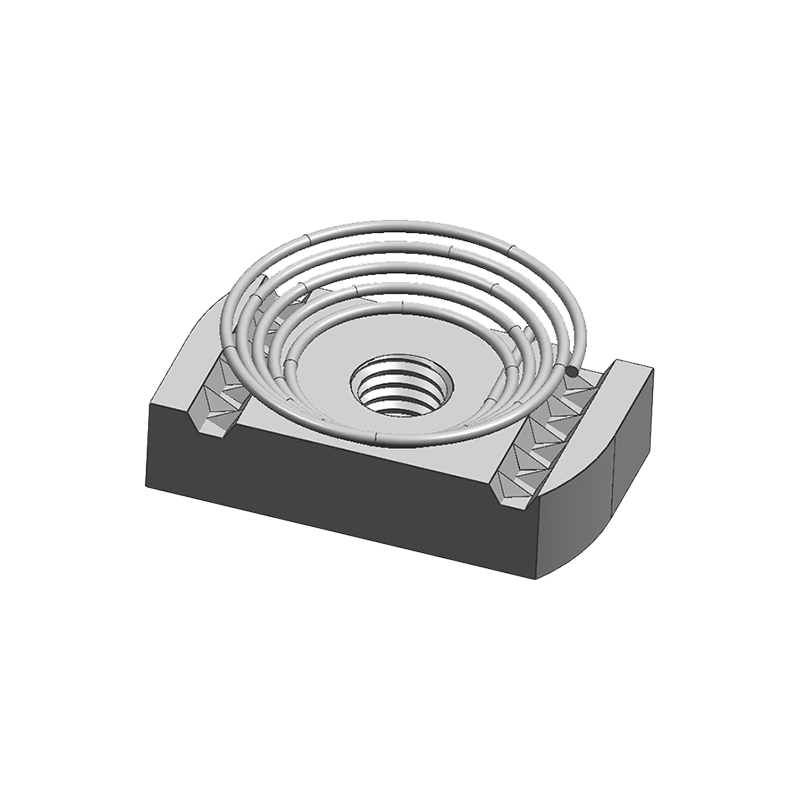

Flat washers also known as plain washers or flat round washers, are simple, flat, and thin disc-shaped pieces of hardware used in various applications to distribute loads, reduce friction, and prevent damage to surfaces. They are commonly placed between the head of a bolt or nut and the surface of the material being fastened to ensure a secure and stable connection. Here are some key features and common uses of flat washers:

Key Features:

Flat Design:

Flat washers have a flat and smooth surface with a central hole. They are usually thinner compared to other types of washers, such as lock washers or spring washers.

Uniform Load Distribution: Their primary function is to evenly distribute the load or pressure applied by the fastener over a larger area. This helps prevent damage to the material being fastened and ensures a more secure connection.

Materials: Flat washers are typically made from various materials, including steel, stainless steel, brass, and plastic, depending on the application's requirements.

Sizes: They come in a range of sizes, with different inner and outer diameters, to accommodate various bolt or screw sizes.

Common Applications:

Bolt and Nut Fastening: Flat washers are commonly used with bolts and nuts to create a stable and secure connection between two or more materials. They provide a cushioning effect and reduce friction during the tightening process.

Construction and Building: In construction and building applications, flat washers are used to reinforce connections between structural components, such as beams, columns, and joists.

Machinery and Equipment: Flat washers are essential in machinery and equipment assembly to distribute the load and ensure proper alignment of components, such as bearings, gears, and pulleys.

Automotive Industry: In the automotive sector, flat washers are used in various vehicle components, such as engines, transmissions, and suspension systems, to maintain secure connections and reduce the risk of material damage.

Plumbing and Pipe Fittings: Flat washers are used with plumbing fixtures, pipe connections, and valves to create watertight seals and prevent leaks.

Electrical and Electronics: In electrical and electronic equipment, flat washers are used to insulate and protect components, reduce vibration, and provide electrical insulation.

DIY and Home Improvement: Flat washers are often used in DIY projects, such as assembling furniture, securing brackets, and general construction or repair tasks.

Aerospace and Aviation: In aerospace and aviation applications, where precision and reliability are crucial, flat washers are used to ensure secure and consistent connections in aircraft components.

Marine Industry: The marine sector relies on corrosion-resistant flat washers in boat and ship construction to protect against the corrosive effects of saltwater.

Flat washers are a fundamental component of fastening systems and are available in various standard sizes and materials. The selection of the right flat washer for a specific application is essential to ensure proper load distribution and connection integrity. Proper installation practices, including torque specifications and fastening procedures, are crucial to maintain the strength and reliability of the connection.

中文简体

中文简体

English

English

Español

Español

Deutsch

Deutsch

.png)

.png)

.png)