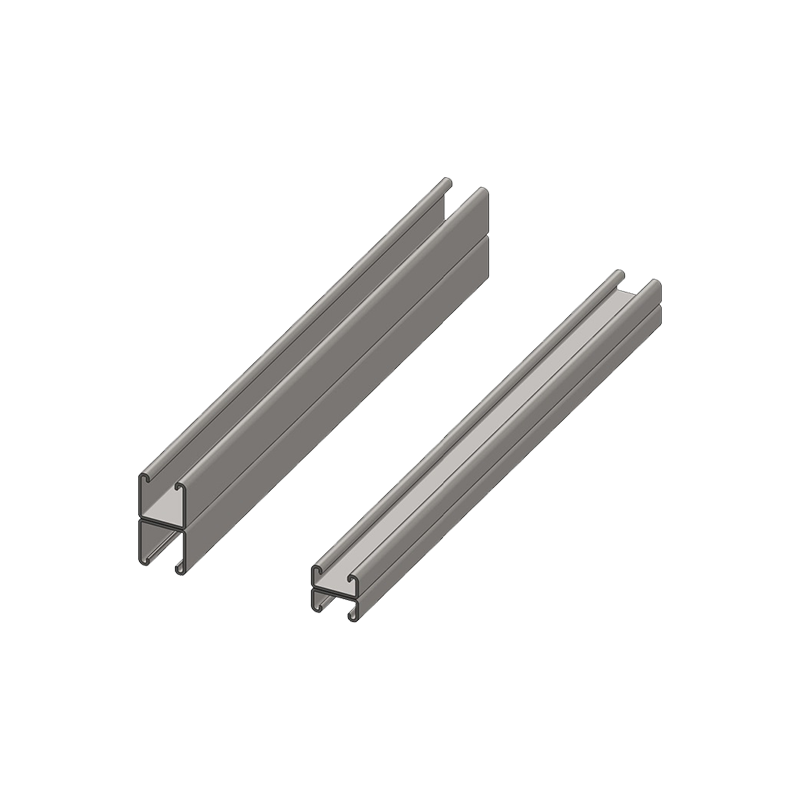

Corrosion protection measures are essential for

channel steel, especially when it is exposed to environmental conditions that can lead to rust and deterioration. Several methods can be used to protect channel steel from corrosion:

Coatings: Applying protective coatings to the surface of channel steel is one of the most common and effective methods to prevent corrosion. Some common coating options include:

Paint: High-quality paints, primers, and rust-inhibiting coatings can provide a protective barrier against moisture and corrosive elements. Epoxy-based paints are often used for steel structures.

Galvanization: Galvanization involves coating channel steel with a layer of zinc to create a protective barrier. This method is highly effective and is often used for outdoor applications, such as fencing, guardrails, and structural support beams.

Powder Coating: Powder coating involves applying a dry powder that adheres to the steel surface and is then baked on. It provides a durable and aesthetically pleasing finish that can resist corrosion.

Cathodic Protection: Cathodic protection systems can be used to protect channel steel in corrosive environments. These systems work by using a sacrificial anode (usually made of zinc or aluminum) that corrodes instead of the steel. This process prevents corrosion from occurring on the channel steel.

Stainless Steel: Using stainless steel channel steel, which contains chromium and other alloying elements, is an effective way to prevent corrosion. Stainless steel is highly resistant to rust and corrosion, making it suitable for marine, chemical, and harsh environments.

Epoxy Coating: Epoxy coatings can provide a robust and chemically resistant protective layer on channel steel. They are often used in environments where exposure to chemicals is a concern, such as in chemical processing plants or wastewater treatment facilities.

Proper Design: Design considerations can also play a role in corrosion prevention. For example, designing structures to allow for adequate drainage and ventilation can help reduce the accumulation of moisture, which is a common cause of corrosion.

Regular Maintenance: Inspecting and maintaining channel steel structures is crucial for long-term corrosion protection. Routine inspections can identify signs of corrosion or damage, allowing for timely repairs or recoating.

Environmental Controls: Controlling the environment around channel steel can help reduce corrosion risk. This may include measures like keeping the steel dry, avoiding exposure to corrosive chemicals, or using protective covers when appropriate.

The choice of corrosion protection method depends on the specific application, the environmental conditions, and the expected service life of the channel steel. Engineers and designers take these factors into account when selecting the most appropriate corrosion protection measures to ensure the longevity and structural integrity of channel steel in various applications.

中文简体

中文简体

English

English

Español

Español

Deutsch

Deutsch

.png)

.png)

.png)