The expected lifespan of a bolt, like any other component, can vary depending on several factors. The lifespan of a

Engineering bolt and its impact on long-term maintenance are influenced by the following considerations:

Material and Corrosion Resistance: The type of material used for the bolt plays a significant role in determining its lifespan. For example, stainless steel bolts are known for their corrosion resistance, which can extend their life in corrosive environments.

Bolts used in harsh environments or exposed to the elements are more susceptible to corrosion, which can shorten their lifespan.

Environmental Conditions: The environmental conditions in which the bolt is placed have a significant impact on its lifespan. Bolts exposed to extreme temperatures, humidity, or chemicals may deteriorate more rapidly. Corrosive environments, such as coastal areas with saltwater exposure, can accelerate corrosion and reduce a bolt's lifespan.

Load and Stress Levels: The load and stress applied to a bolt also affect its lifespan. Bolts that are constantly subjected to high loads or dynamic stresses may experience fatigue and eventually fail over time. Properly sizing and specifying bolts to match the expected loads is essential for a longer lifespan.

Installation Quality: The quality of bolt installation, including torque or tension levels, and whether it is installed correctly, affects the bolt's ability to withstand loads.

Poorly installed bolts may fail prematurely.Vibration and Movement: Bolts in applications with significant vibration or movement may

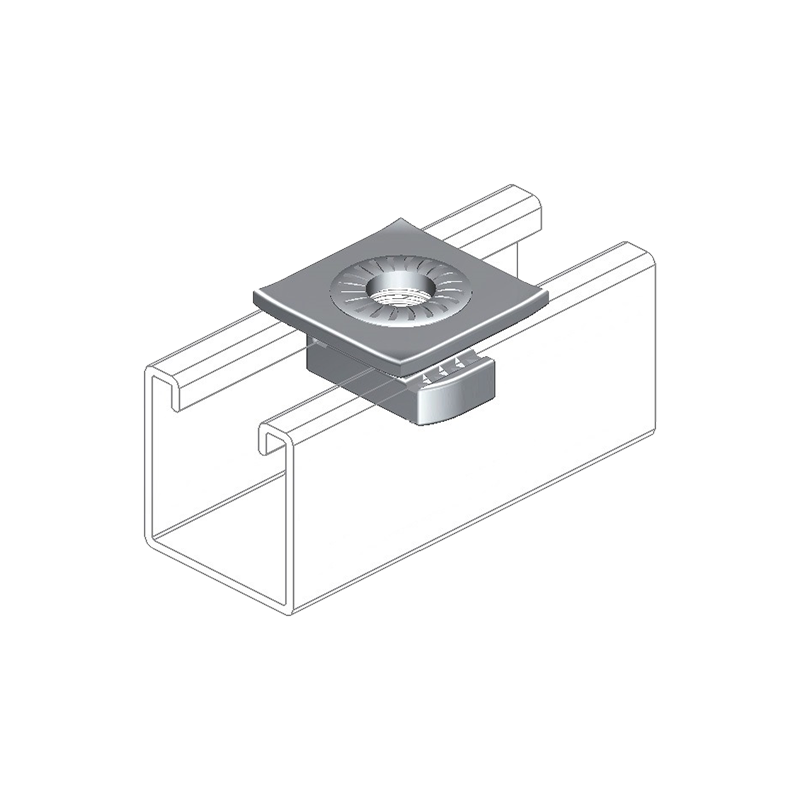

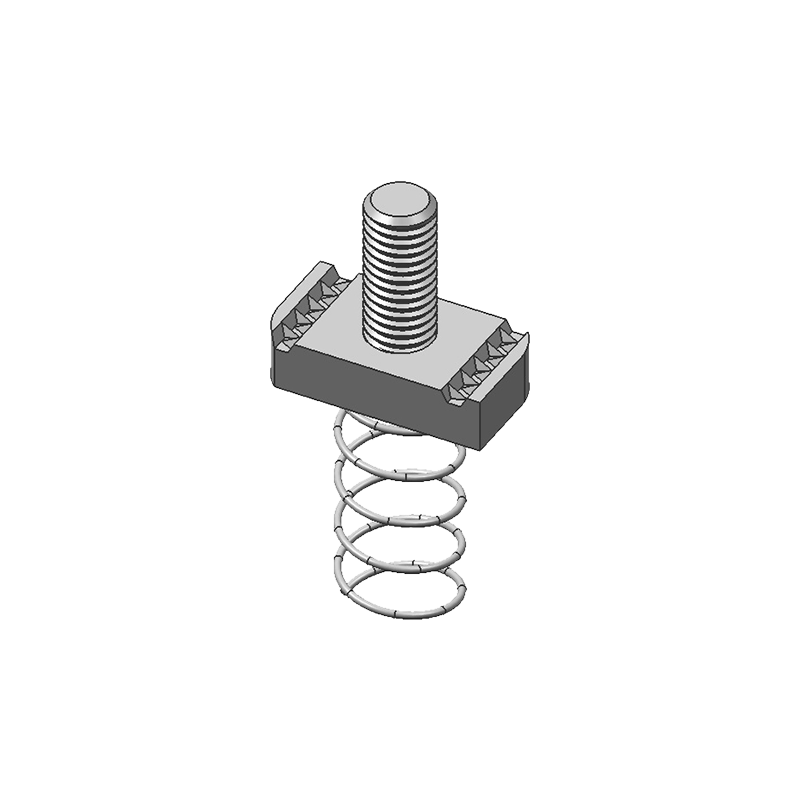

experience additional stress and fatigue, potentially reducing their lifespan. Adequate fastening methods, such as the use of lock washers, thread-locking adhesives, or prevailing torque nuts, can help mitigate this.

Maintenance Practices: Regular inspection and maintenance play a crucial role in prolonging a bolt's lifespan. Bolts and fasteners that are inspected, lubricated, and replaced as needed are more likely to last longer. Neglecting maintenance can lead to premature failure.

Material Quality: The quality of the bolt material can vary between manufacturers. High-quality bolts made to industry standards are more likely to have a longer lifespan.

Choosing reputable suppliers is important.Material Degradation: Over time, even in non-corrosive environments, all materials can degrade due to factors like fatigue, stress, and cyclic loading. Understanding the expected degradation rate is vital in maintenance planning.

Design and Application: The design and application of the bolt also play a role. Bolts in critical structural applications, where failure could have severe consequences, may need more frequent inspections and replacement.

Maintenance Schedule: Developing a maintenance schedule that includes bolt inspection and replacement based on anticipated lifespan is essential. This schedule can help prevent unexpected failures and ensure the safety and reliability of the structure or equipment.

Replacement and Upgrades: As bolts near the end of their lifespan or show signs of wear and degradation, it is crucial to replace them promptly with new, properly sized and specified bolts. In some cases, upgrades to high-strength or corrosion-resistant bolts may be warranted.

In summary, the expected lifespan of a bolt depends on a combination of factors, including material, environmental conditions, load, installation, and maintenance. Regular inspection and maintenance practices are essential for ensuring that bolts continue to perform their

function safely and reliably over time. Neglecting these factors can lead to premature bolt failure and the need for costly repairs or replacements.

中文简体

中文简体

English

English

Español

Español

Deutsch

Deutsch

.png)

.png)

.png)

.png)